{{i.title_en}}

SPN series planetary Reducer

MOQ: 10 PCS

Note: If you have any questions,please contact us

- 1.SPN series planetary reducer adopts two structural forms of coaxial type and angle type, with 1-4-stage transmission.

- 2.The box body is made of nodular cast iron with high bearing capacity. The sun gear and planetary gear are meshed with straight teeth. The gears and bevel gears are hardened, shaped and ground.

- 3.The internal gear ring is mainly quenched and tempered at high temperature. The gear teeth are designed for infinite fatigue life according to the given torque.

- 4.This series of products are widely used in metallurgy, mining, cement, chemical industry, building materials, engineering machinery, hoisting, port ships, belt transportation and other subdivided fields.

- 5.It can be flexibly combined into multiple types. It can be combined with four series of products to make the transmission ratio larger and the application range wider

- SPN..L..PC..D..E

- SPN..L..HZ..FAD..O

- SPN..R..FP..AD..B..GO

- SPN..L..VK..D..T

Zhejiang Supror Machinery Technology Co.,Ltd

Since:

2003

Product Description

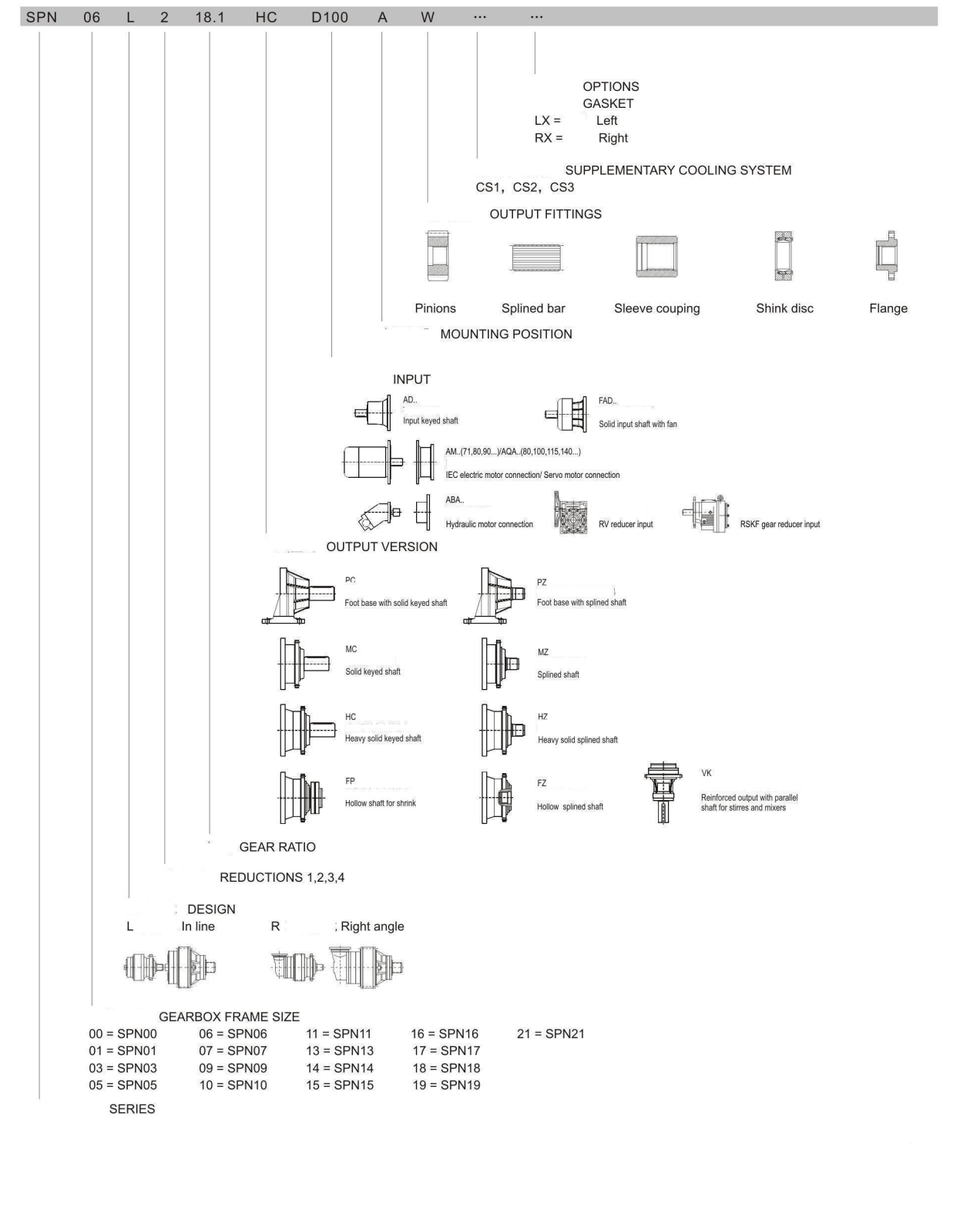

SPN...Gearbox designation

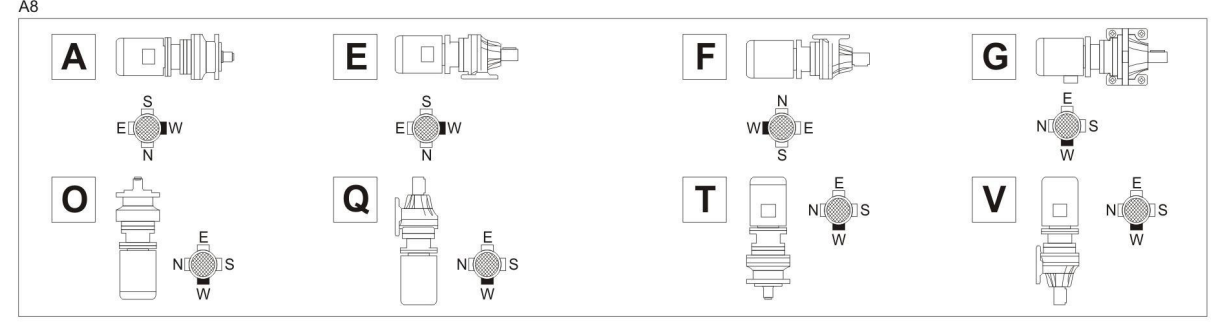

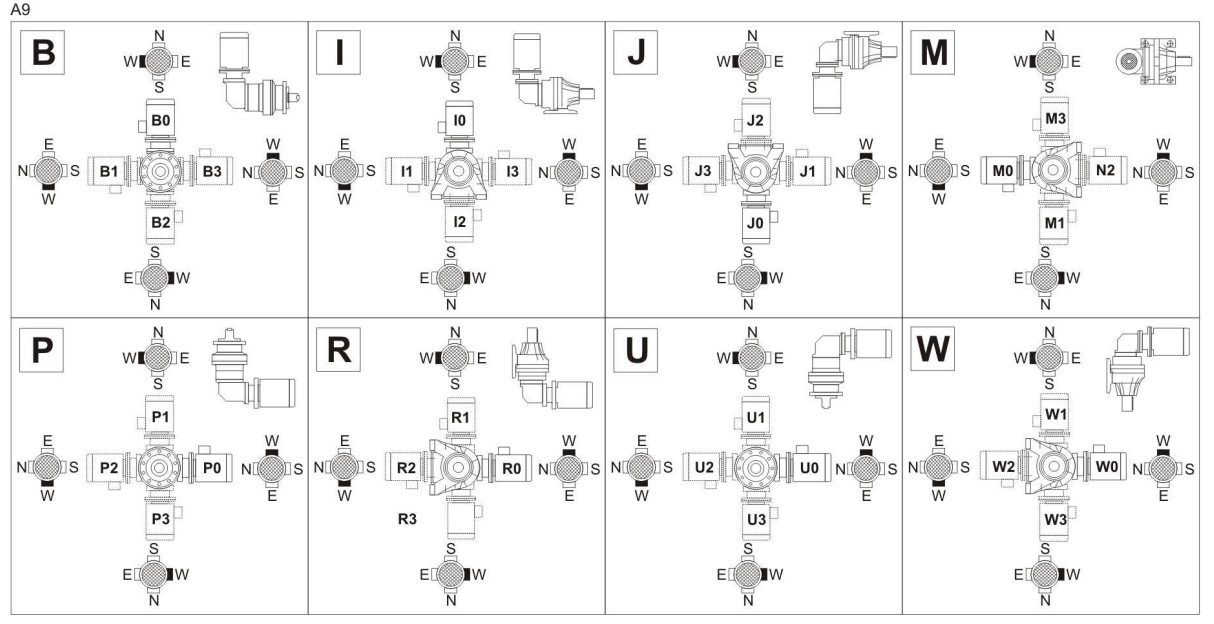

Mounting position

The product designation is only complete when the mounting position is also specified

Please refer to table (A8)for in-line gear units and to (A9) for right angle drives ln line units

Right angle unit

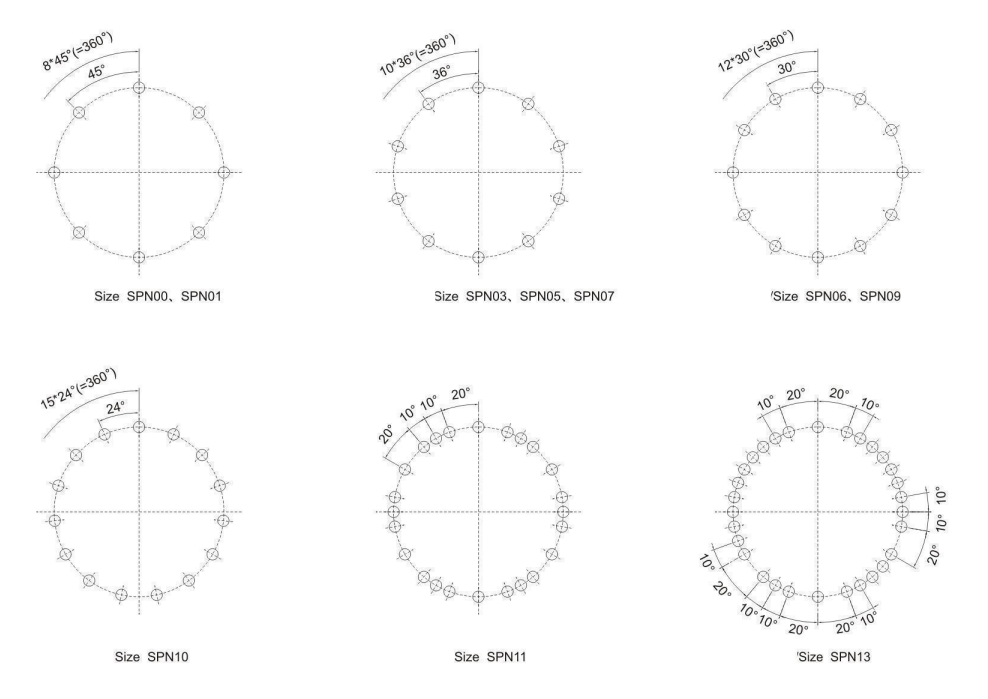

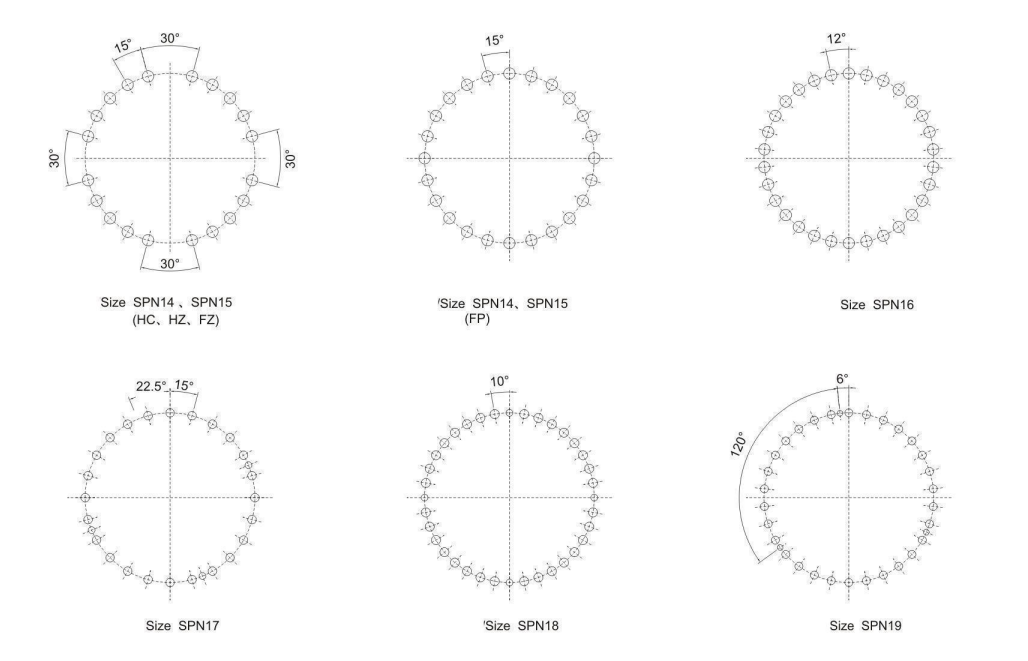

Hole Patterns on Output Flanges(Viewing on output shaft)

SPN series basic features are:

18 size:

output torque up to 500,000 Nm

output power up to 450 kw

ratios from 3.5:1 to 3000:1

Modular design:

in-line with 1 to 4 reductions

right angle (spiral bevel gear set into first stage )with 2 to 4 reduction.

Flange-mounted,foot-mounted and shaft-mounted output

Output shafts with keyway,splined, splined hollow shafts,hollow shafts for shaft-mounting with shrink disc

Input adapters for:

electric motors to IEC standards design B5

input shafts

servomotors

hydraulic motor setting

Installation accessories:

flanges

pinions

Spline bars

shrink discs

More design features:

high ratio of transmissible torque to overall dimensions

high radial and axial load capacity of output shafts thanks to tapered roller bearings fitted on the H versions

high efficiency

inner parts are connected using grooved sections instead of tabs

planetary gears of reduction stages mounted to floating holders to ensure

maximum load distribution among planetary gears

housing from ductile cast iron

OUTPUT TORQUE

Reference torque M2[Nm]

Indicative output torque to easily establish the performance class for each gearbox basic size

Nominal torque Mn2[Nm]

The condition is that the torque of the gearbox can be transmitted safely:

Uniform load,the safety factor is 1

Theoretical life is 10000 hours

Maximum torque M2max[Nm]

It is the output torque that the reduction unit can withstand in static or highly intermittent conditions.

It is considered as instantaneous load peak torque or stanting torque under load.

Required torqueMr2 [Nm]

This is the torque corresponding to application requirement.

It must always be equal to or less than rated output torque Mn2 of the selected geart

Calculate torque Mr2[Nm]

Torque value to be used for selecting the gearbox,considering required torque Mr2 and service factor fs,and is obtained by formula

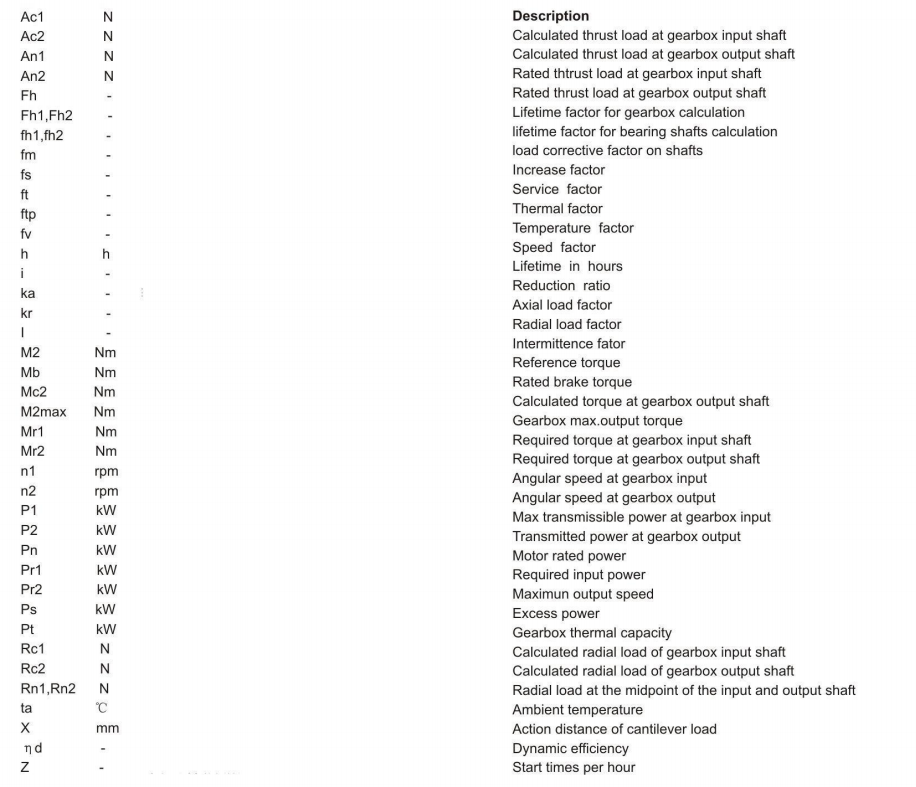

Symbols and units of measure

中文

中文 English

English Español

Español Français

Français