{{i.title_en}}

OMS Hydraulic Motor 315CCM for Danfoss 151B-3118

MOQ: 100 PCS

Note: If you have any questions,please contact us

- 1. Advanced manufacturing devices for the geroler gear set, which use low pressure of start-up, provide smooth and reliable operation and high efficiency.

- 2. The output shaft adapts in adapts in tapeered roller bearings that permit high axial and radial forces.

- 3. The case can offer applications of high pressure and high torque in the wide of applications.

- 4. Advanced design in disc distribution flow, which can automatically compensate in operating with high volum efficiency and long life. Provide smooth and reliable operation.

- 5. The new series motor is suitable for vehicles with greater loads and pressures drop.

- 315CC

XINGTAI FEIYUE HYDRAULIC PARTS FACTORY

Since:

1985

Product Description

Hydraulics OMS type, low speed high torque (LSHT) hydraulic motors deliver high output torque atan economical price. They feature tapered roller bearings on the output shaft which permit high radial and axial loads. The advanced valving design minimizes cross port leakage resulting in highvolumetric efficiency and constant output speeds at varying pressures.

The OMS Series type hydraulic motor takes advantage of the latest proven technology providingextended life, performance and reliability for medium duty applications. Industry standard mounting flanges and output shafts allow the OMS Series motor to be easily incorporated into your application.

BMS Main Specification

| TYPE | BM5 | BM5 | BM5 | BM5 | BM5 | BM5 | BM5 | BM5 | BM5 | |

| OMS 80 | OMS 100 | OMS 125 | OMS 160 | OMS 200 | OMS 250 | OMS 315 | OMS 400 | OMS 495 | ||

| Displacement(ml/r) | 80.6 | 100.8 | 125 | 154 | 194 | 243 | 311 | 394 | 495 | |

Max.speed(rpm) | Rated | 675 | 540 | 432 | 337 | 270 | 216 | 171 | 135 | 110 |

| Continuous | 800 | 748 | 600 | 470 | 375 | 300 | 240 | 185 | 155 | |

| Intermittent | 988 | 900 | 720 | 560 | 450 | 360 | 280 | 225 | 185 | |

Max.TORQUE(N.m) | Rated | 175 | 220 | 273 | 445 | 505 | 620 | 700 | 765 | 780 |

| Continuous | 225 | 290 | 365 | 485 | 586 | 708 | 880 | 880 | 910 | |

| Intermittent | 305 | 390 | 480 | 590 | 705 | 860 | 1000 | 980 | 990 | |

Max.output(KW) | Rated | 12 | 12.4 | 12.4 | 12.4 | 12.4 | 12.4 | 11.2 | 9.6 | 8.6 |

| Continuous | 16 | 18 | 18 | 18.1 | 18.1 | 18 | 17 | 11 | 9 | |

| Intermittent | 20 | 22 | 23 | 25 | 24 | 23.8 | 20.2 | 12 | 11 | |

Max.pressure(Mpa) | Rated | 16 | 16 | 16 | 19 | 19 | 18 | 16 | 14 | 12 |

| Continuous | 20.05 | 20.5 | 20.5 | 21 | 21 | 20 | 20 | 16 | 14 | |

| Peak | 27.05 | 27.5 | 27.5 | 26 | 25 | 25 | 24 | 19 | 15 | |

| Intermittent | 29.5 | 29.5 | 29.5 | 28 | 27 | 27 | 26 | 21 | 17.5 | |

Max.inlet(L/min) | Rated | 65 | 75 | 75 | 75 | 75 | 75 | 75 | 75 | 75 |

| Continuous | 80 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | |

| Intermittent | 21 | 21 | 21 | 21 | 21 | 21 | 21 | 21 | 21 | |

| Max.inlet pressure(Mpa) | Continuous | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Intermittent | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | |

| Weight(kg) | 9.8 | 10 | 10.3 | 10.7 | 11.1 | 11.6 | 12.3 | 13.2 | 14.3 | |

| 1. Continuous pressure:Max.value of operating motor continuously. | ||||||||||

| 2.Intermittent pressure:Max.value of operating motor in 6 seconds per minute . | ||||||||||

| 3.Peak pressure:Max.value of operating motor in 0.6 second per minute. | ||||||||||

| 4.The optimum operating situation should be at the 1/3-2/3 of the continuous operating situation. | ||||||||||

Replace DANFOSS No.

| 151F-0500 | 151F-0522 | 151F-0544 | 151F-2206 | 151F-2242 | 151F-2305 | 151F-2327 | 151F-2354 |

| 151F-0501 | 151F-0523 | 151F-0545 | 151F-2207 | 151F-2243 | 151F-2306 | 151F-2328 | 151F-2355 |

| 151F-0502 | 151F-0524 | 151F-0546 | 151F-2208 | 151F-2244 | 151F-2307 | 151F-2329 | 151F-2356 |

| 151F-0503 | 151F-0525 | 151F-0547 | 151F-2209 | 151F-2245 | 151F-2308 | 151F-2330 | 151F-2357 |

| 151F-0504 | 151F-0526 | 151F-0548 | 151F-2210 | 151F-2246 | 151F-2309 | 151F-2331 | 151F-2358 |

Replace EATON/CHAR-LYNN

| 104-1001 | 104-1032 | 104-1066 | 104-1198 | 104-1376 | 104-1421 | 105-1060 | 105-1096 |

| 104-1002 | 104-1033 | 104-1067 | 104-1199 | 104-1377 | 104-1422 | 105-1071 | 105-1134 |

| 104-1003 | 104-1034 | 104-1068 | 104-1200 | 104-1378 | 104-1423 | 105-1072 | 105-1135 |

| 104-1004 | 104-1036 | 104-1087 | 104-1201 | 104-1379 | 105-1001 | 105-1073 | 105-1136 |

| 104-1005 | 104-1037 | 104-1088 | 104-1202 | 104-1380 | 105-1002 | 105-1074 | 105-1137 |

Hydraulic motor spare part and production line

1.Hydraulic motor body BEFORE processing.

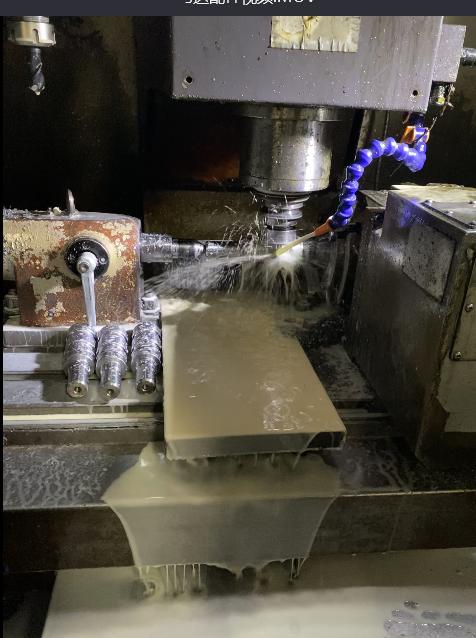

2.Picture of shell processing equipment.

3.Hydraulic motor body AFTER processing.

1. Hydraulic motor inside contact Shaft BEFORE Processing

2. Equipment for processing internal contact shafts

3.Hydraulic motor inside contact shaft AFTER processing.

1.Hydraulic motor drlve shaft BEFORE processing.

2.Hydraulic motor drlve shaft processing machine

3. Hydraulic motor drlve shaft AFTER processing.

1.Hydraulic motor stator BEFORE processing

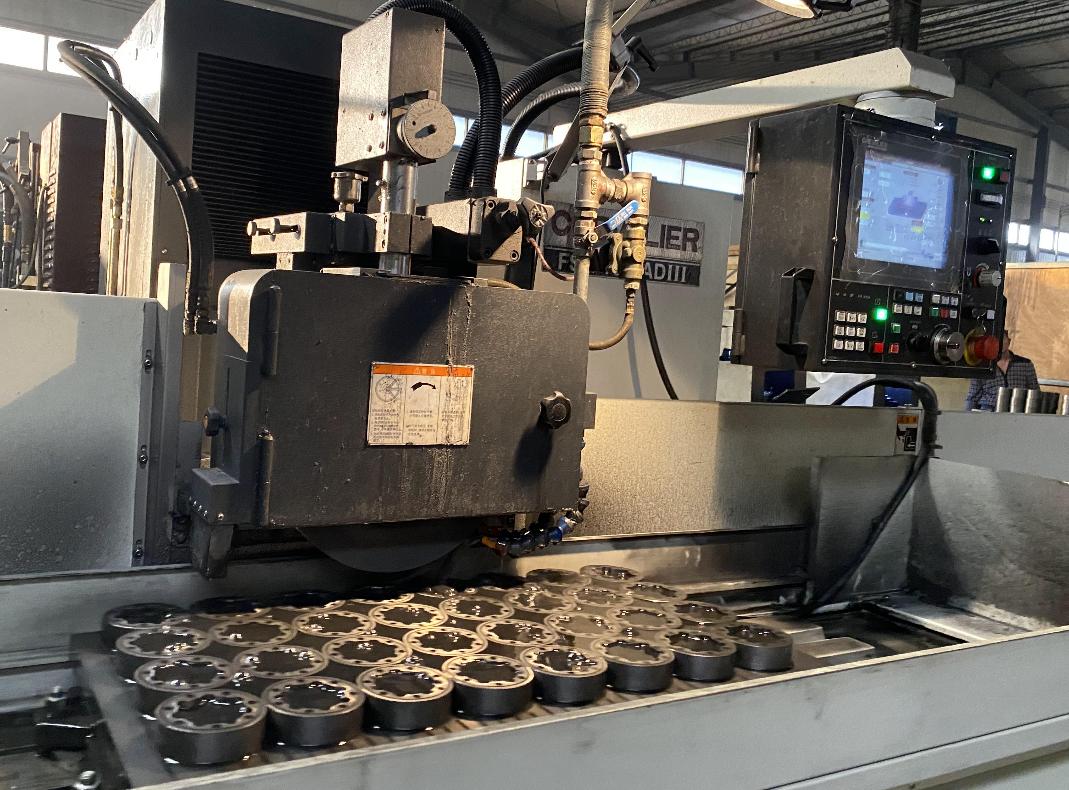

2.Hydraulic motor stator processing machine

3.Hydraulic motor stator AFTER processing

Outgoing pictures and product certification

Product list :fei yue catalogue 2021

中文

中文 English

English Español

Español Français

Français