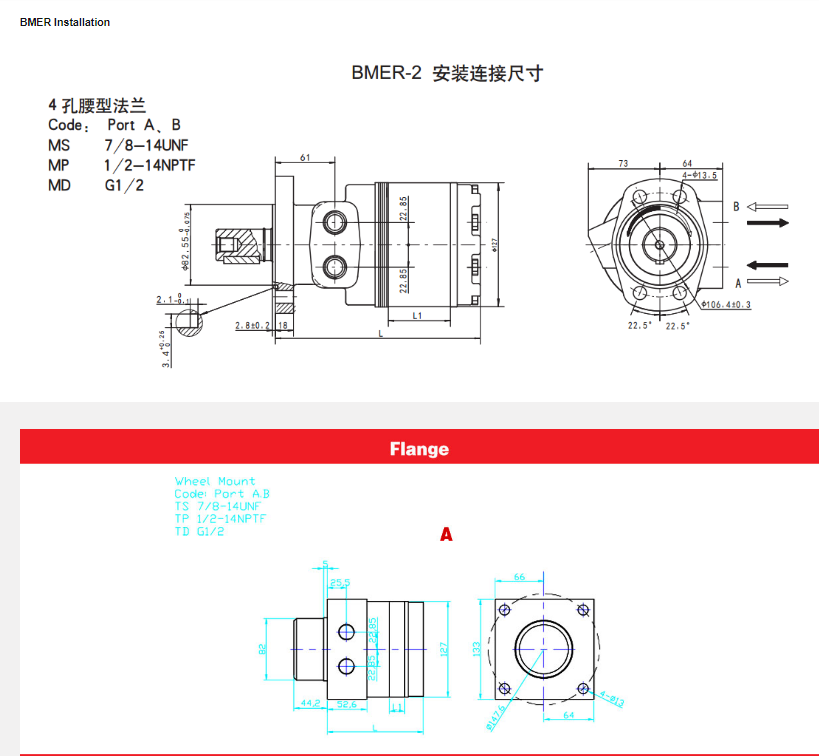

{{i.title_en}}

Hydraulic Motor BMER series for Danfoss

MOQ: 100 PCS

Note: If you have any questions,please contact us

- 1. Compact design, which provide small volume,high power and low weight.

- 2. Credible design,for shaft seal,which can bear high pressure and be used in parallel or in series.

- 3. Direction of shaft rotation and speed can be controlled easily and smoothly.

- 4. Best combination of efficiency and economy in medium load applications

- 5. Advanced manufacturing devices for the Gerotor gear set, high efficiency and long life.

- 160CCM

XINGTAI FEIYUE HYDRAULIC PARTS FACTORY

Since:

1985

Product Description

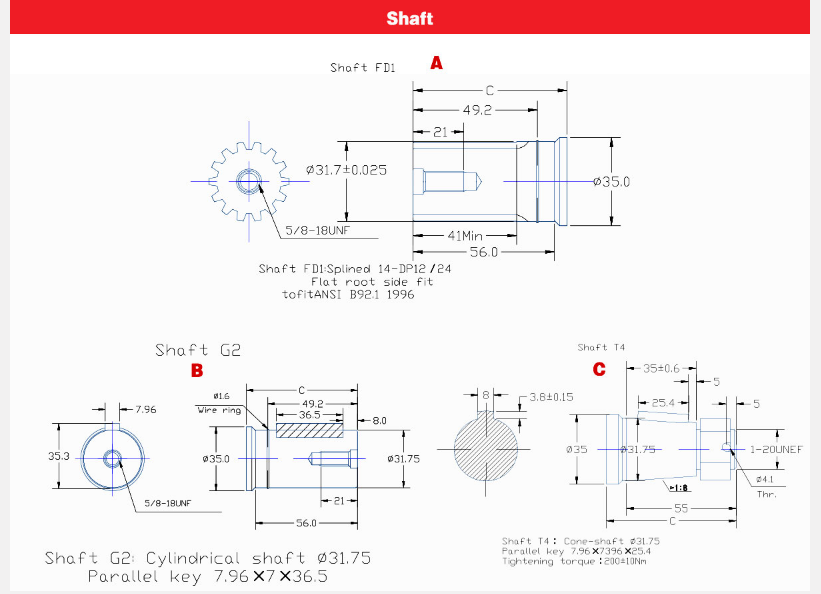

BMER series orbital hydraulic motor is an advanced hydraulic motor with high-speed distribution structure. The series of motors use inlaid-column rotary stator . It has the characteristics of high working pressure, high working efficiency, good stability at low speed, high volume efficiency, good efficiency and long working life. On the basis of the standard structure, the multi-functional variant design can be designed according to the user's needs.

Product list :fei yue catalogue 2021

Its characteristics are:

The advanced design of rotor stator parameters has the advantages of low starting pressure, high efficiency and good retention.

High working pressure and high output torque. With needle roller bearing structure, bearing axle and strong radial load capacity, the motor can directly drive the working mechanism and expand the scope of use.

Advanced high-speed flow distribution structure ensures high accuracy of motor flow distribution, strong automatic compensation ability after wear, high volume efficiency, long life of motor, stable speed of motor and stable load speed characteristics.

The valve distribution system has the characteristics of low leakage. The rotating speed of the valve plate is six times of the output speed, which makes the motor have high flow distribution accuracy, strong automatic compensation ability after wear and tear, and ensures high volume efficiency. The motor has the characteristics of smooth movement at low speed.

Main Specification

| Type | BMER 160 | BMER 200 | BMER 250 | BMER 300 | BMER 350 | BMER 475 | BMER 750 | |

| Displacement | 156 | 196 | 257 | 296 | 345 | 462 | 745 | |

| Max.Speed(rpm) | Continuous | 375 | 330 | 290 | 250 | 220 | 160 | 100 |

| Intermittent | 470 | 425 | 350 | 315 | 270 | 195 | 120 | |

Max.Turque(N.m) | Continuous | 450 | 530 | 700 | 810 | 905 | 1085 | 1050 |

| Intermittent | 525 | 600 | 790 | 930 | 1035 | 1180 | 1180 | |

| Peak value | 590 | 750 | 980 | 1120 | 1285 | 1260 | 1370 | |

| Max.Power(KW) | Continuous | 15.0 | 15.5 | 17.5 | 18.0 | 17.5 | 14.5 | 8.0 |

| Intermittent | 17.5 | 18.0 | 20.0 | 21.0 | 20.0 | 16.5 | 10.0 | |

Max.Pressure(Mpa) | Continuous | 20.5 | 20.5 | 20.5 | 20.5 | 20.5 | 17.5 | 10.5 |

| Intermittent | 24 | 24 | 24 | 24 | 24 | 19 | 12 | |

| Peak value | 27.6 | 27.6 | 27.6 | 27.6 | 27.6 | 20.5 | 14 | |

| Max.Flow(L/min) | Continuous | 60 | 70 | 75 | 80 | 80 | 75 | 75 |

| Intermittent | 75 | 85 | 90 | 95 | 95 | 90 | 90 | |

Rated speed and torque refer to the output value under rated flow and pressure.

*Continuous value refers to the maximum value that the displacement motor can work continuously.

*Intermittent value refers to the maximum value of the displacement motor working for 6 seconds in a minute.

*Peak value is the maximum of 0.6 seconds in a minute for the displacement motor.

Hydraulic motor spare part and production line:

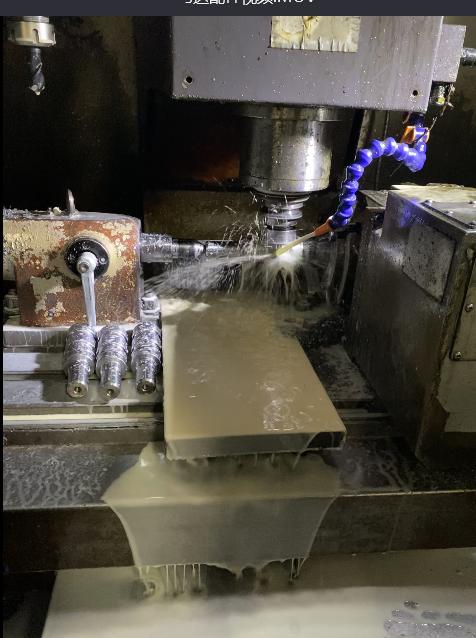

1.Hydraulic motor body BEFORE processing.

2.Picture of shell processing equipment.

3.Hydraulic motor body AFTER processing.

1. Hydraulic motor inside contact Shaft BEFORE Processing

2. Equipment for processing internal contact shafts

3.Hydraulic motor inside contact shaft AFTER processing.

1.Hydraulic motor drlve shaft BEFORE processing.

2.Hydraulic motor drlve shaft processing machine

3. Hydraulic motor drlve shaft AFTER processing.

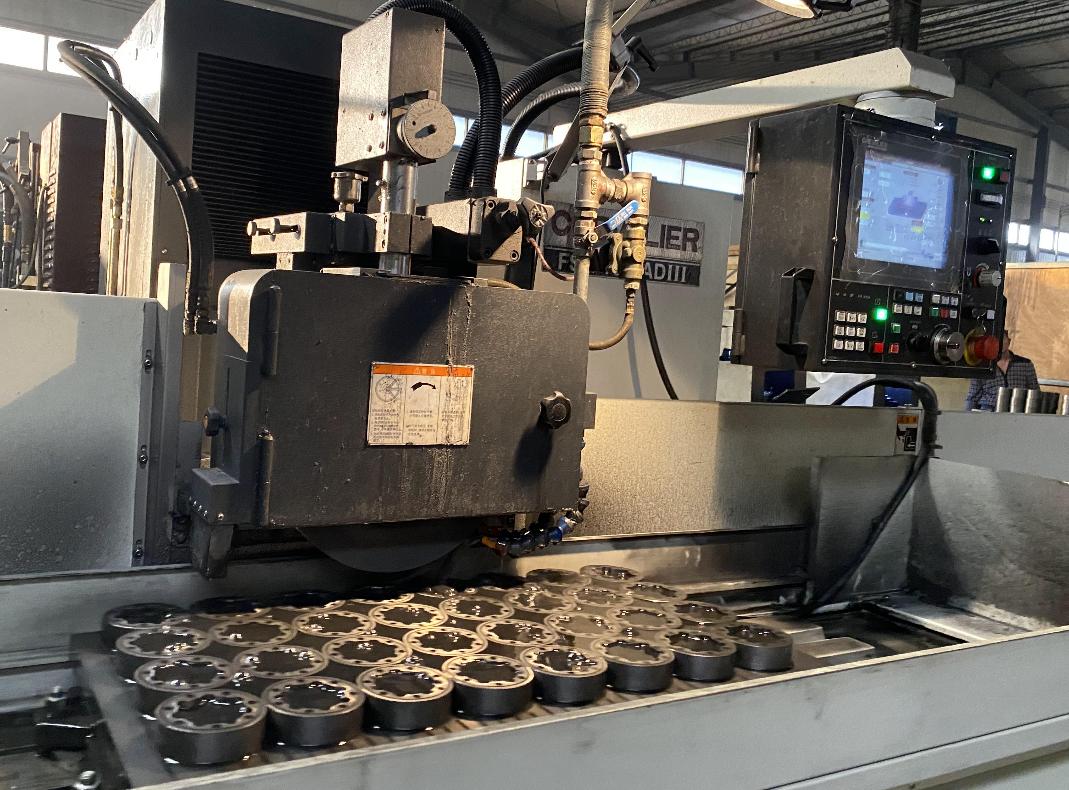

1.Hydraulic motor stator BEFORE processing

2.Hydraulic motor stator processing machine

3.Hydraulic motor stator AFTER processing

Outgoing pictures and product certification

中文

中文 English

English Español

Español Français

Français