{{i.title_en}}

OMER 250CCM Low Leakage Cycloidal Motor Hydraulic Orbital Motor

MOQ: 100 PCS

Note: If you have any questions,please contact us

- 1.Advanced manufacturing devices for the Geroler gear set, which use low pressure ofstart-up,provide smooth and reliable operation and high efficiency.

- 2.The output shaft adapts in needle roller bearings that permit high axial and radial forces.The case can offers capacities of high pressure and high torque in the wide of applications.

- 3.Advanced design in high speed distribution flow, which can automatically compensate in operating with high volume efficiency and long life, provide smooth and reliable operation.

- 4.Lowest leakage rate, most accurate timing methods.Commutator rotates 6x faster than shaft speed. It make the distribution in a high precision reduces life-cycle cost,maintain high volume efficiencies and can run very smoothly at low speed,gear box not r

- OMER 250CCM

XINGTAI FEIYUE HYDRAULIC PARTS FACTORY

Since:

1985

Product Description

OMER 250CCM Low Leakage Cycloidal Motor Hydraulic Orbital Motor

OMER SERIES HYDRAULIC MOTOR

BMER series motor adapt the advanced Geroler gear set designed with high speed distribution flow and high pressure, and have good stability in low speed, and can keep high volume efficiency. The unit can be supplied the individual variant in operating multifunction in accordance with requirement of applications.

Characteristic features:

1.Advanced manufacturing devices for the Geroler gear set, which use low pressure ofstart-up,provide smooth and reliable operation and high efficiency.

2.The output shaft adapts in needle roller bearings that permit high axial and radial forces.The case can offers capacities of high pressure and high torque in the wide of applications.

3.Advanced design in high speed distribution flow, which can automatically compensate in operating with high volume efficiency and long life, provide smooth and reliable operation.

4.Lowest leakage rate, most accurate timing methods.Commutator rotates 6x faster than shaft speed. It make the distribution in a high precision reduces life-cycle cost,maintain high volume efficiencies and can run very smoothly at low speed,gear box not required.

OMER 250CCM Low Leakage Cycloidal Motor Hydraulic Orbital Motor Main Specification:

| Type | BMER 125 | BMER 160 | BMER 200 | BMER 230 | BMER 250 | BMER 300 | BMER 350 | BMER 375 | BMER 400 | BMER 475 | BMER 540 | BMER 650 | BMER 750 | |

| Geometric displacement(cm'/rev.) | 118 | 156 | 196 | 228 | 257 | 296 | 345 | 371 | 405 | 462 | 540 | 647 | 745 | |

| Max.speed (rpm) | cont. | 360 | 375 | 330 | 290 | 290 | 250 | 220 | 200 | 185 | 160 | 140 | 115 | 100 |

| int. | 490 | 470 | 425 | 365 | 350 | 315 | 270 | 240 | 220 | 195 | 170 | 138 | 120 | |

| Max.torque (N m) | cont. | 325 | 450 | 530 | 625 | 700 | 810 | 905 | 990 | 1010 | 1085 | 980 | 1015 | 1050 |

| int. | 380 | 525 | 600 | 710 | 790 | 930 | 1035 | 1140 | 1180 | 1180 | 1240 | 1250 | 1180 | |

| peak | 450 | 590 | 750 | 870 | 980 | 1120 | 1285 | 1360 | 1360 | 1260 | 1380 | 1380 | 1370 | |

| Max.output (kW) | cont. | 12.0 | 15.0 | 15.5 | 16.0 | 17.5 | 18.0 | 17.5 | 16.5 | 15.5 | 14.5 | 11.5 | 10.0 | 8.0 |

| int. | 14.0 | 17.5 | 18.0 | 19.0 | 20.0 | 21.0 | 20.0 | 19.0 | 18.0 | 16-S | 1S.0 | 12.0 | 10.0 | |

| Max. pressure drop (MPa) | cont. | 20.5 | 20.5 | 20.5 | 20.5 | 20.5 | 20.5 | 20.5 | 20.5 | 19 | 17.5 | 14 | 12 | 10.5 |

| int. | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 22.5 | 19 | 17.5 | 15.5 | 12 | |

| peak | 27.6 | 27.6 | 27.6 | 27.6 | 27.6 | 27.6 | 27.6 | 27.6 | 25 | 20.5 | 20.5 | 17.5 | 14 | |

| Max.flow (L/min) | cont. | 45 | 60 | 70 | 70 | 75 | 80 | 80 | 7S | 75 | 75 | 75 | 75 | 75 |

| int. | 60 | 75 | 85 | 85 | 90 | 95 | 95 | 90 | 90 | 90 | 90 | 90 | 90 | |

1.Continuous pressure:Max.value of operating motor continuously.

2.Intermittent pressure:Max.value of operating motor in 6 seconds per minute.

3.Peak pressure:Max.value of operating motor in 0.6 second per minute.

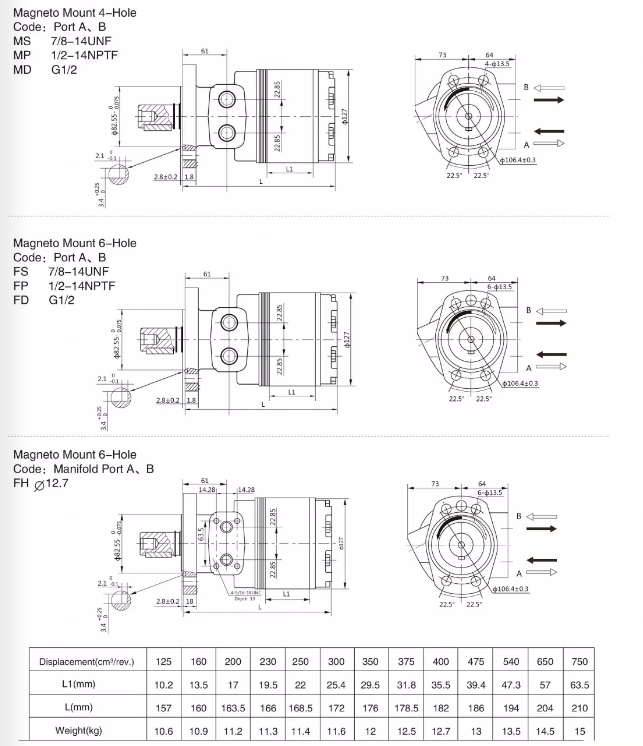

BMER-2 Dimensions mounting Data

Hydraulic motor spare part and production line:

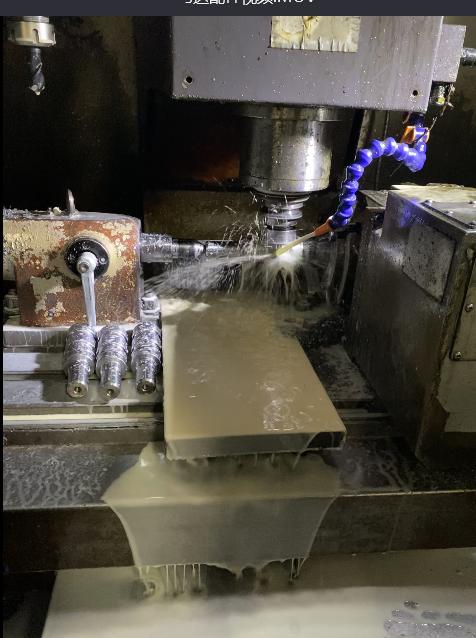

1.Hydraulic motor body BEFORE processing.

2.Picture of shell processing equipment.

3.Hydraulic motor body AFTER processing.

1. Hydraulic motor inside contact Shaft BEFORE Processing

2. Equipment for processing internal contact shafts

3.Hydraulic motor inside contact shaft AFTER processing.

1.Hydraulic motor drlve shaft BEFORE processing.

2.Hydraulic motor drlve shaft processing machine

3. Hydraulic motor drlve shaft AFTER processing.

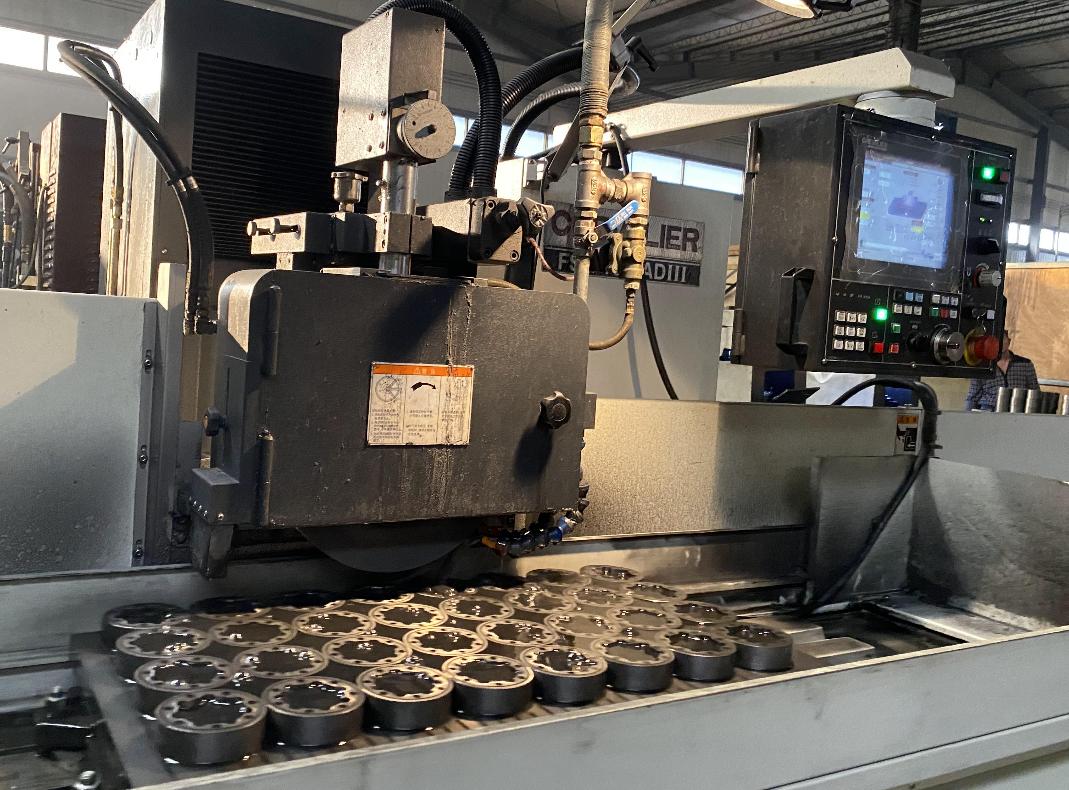

1.Hydraulic motor stator BEFORE processing

2.Hydraulic motor stator processing machine

3.Hydraulic motor stator AFTER processing

Outgoing pictures and product certification

Product list :fei yue catalogue 2021

中文

中文 English

English Español

Español Français

Français