{{i.title_en}}

OMT 160CCM High Speed Cycloidal Orbital for Danfoss Hydraulic Motor

MOQ: 100 PCS

Note: If you have any questions,please contact us

- 1. Advanced manufacturing devices for the geroler gear set, which use low pressure of start-up, provide smooth and reliable operation and high efficiency.

- 2. Advanced design in distribution flow, which can automatically compensate in operating with high volume efficiency and long life, provide smooth and reliable operation.

- OMT 160CCM

XINGTAI FEIYUE HYDRAULIC PARTS FACTORY

Since:

1985

Product Description

OMT 160CCM High Speed Cycloidal Orbital for Danfoss Hydraulic Motor

Ordering Information

| Product NO | Displacement (CCM) | Mounting Flange(MM) | Shaft (MM) | Port Size | Drain Port | Shaft end thread | Mounting holes | Oil Port shape | Parallel key width(MM) |

| BMT/OMT |

160/200/230/250/315 /400/500/630/800 | 125/127 | 40 | G3/4 | G1/4 | M8 | 4 | S | 12

|

The OMT/BMT series orbital hydraulic motor produced by Fei Yue is one disc valve type gerolor motor,Advanced design of disc distribution flow, which can provide improved performance at low speed higher volumetric for the automaticalty compensate wear.

Double taper roller bearings permit high radial loads, can be used on heavy vehicles/machinery in traction drive applicationsOMT/BMT series orbital hydraulic motors are widely applied in agriculture machinery, fishing machinery, plastic industry, mining, and construction machinery, especially fitted to lower load applications, such as plastic injection mold machine, cleaner, grass cutter,Winches, Conveyors, Slews, Sweeper Drives, Augers, Cutters, Mowers and Chippers etc.

hydraulic concrete mixer motor(OMT/BMT)

Flange:

4-Ø14 Square-flangeØ160,pilotØ125×9

4-Ø14.5Square-flangeØ162,pilotØ127×9

4-Ø18 Wheel-flangeØ200,pilotØ160×7

Shaft:

Shaft Ø40 , parallel key 12×8×70

Shaft Ø38.1 ,parallel key 9.52×9.52×57.15

Shaft Ø38.1 ,splined tooth 17-DP12/24

Shaft Ø38.1 ,splined tooth 17-DP12/24

Cone-shaft 1:10 Ø45 ,parallel key B12×8×28

Cone-shaft 1:8 Ø45 ,parallel key 11.13×11.13×31.75

shaft Ø34.85,Splined key 6-34.85×28.14×8.64

shaftØ31.75 ,parallel key 7.96×7.96×40

Shaft Ø31.75,splined tooth 14-DP12/24

Port and drain port:

G3/4 Manifold Mount,4-M10 , G1/4

M27×2 Manifold Mount,4-M10, M14×1.5

1-1/16-12UN O-ring, 9/16-18UNF

1-1/16-12UN O-ring, 7/16-20UNF

G3/4,G1/4

M27×2,M14×1.5

Product list :fei yue catalogue 2021

OMT/BMT Main Specification

| Type | BMT 160 | BMT 200 | BMT 230 | BMT 250 | BMT 315 | BMT 400 | BMT 500 | BMT 630 | BMT 800 | |

| Geometric displacement(cm3/rev.) | 161.1 | 201.4 | 232.5 | 251.8 | 326.3 | 410.9 | 523.6 | 629.1 | 801.8 | |

Max.speed (rpm) | Rated | 470 | 475 | 412 | 381 | 294 | 228 | 183 | 150 | 121 |

| Continuous | 625 | 625 | 536 | 500 | 380 | 305 | 240 | 196 | 154 | |

| Intermittent | 780 | 750 | 643 | 600 | 460 | 365 | 285 | 233 | 185 | |

Max.torque(N.m) | Rated | 379 | 471 | 530 | 582 | 758 | 896 | 1063 | 1156 | 1207 |

| Continuous | 470 | 590 | 670 | 730 | 950 | 1080 | 1220 | 1318 | 1464 | |

| Intermittent | 560 | 710 | 821 | 880 | 1140 | 1260 | 1370 | 1498 | 1520 | |

| Peak value | 669 | 838 | 958 | 1036 | 1346.3 | 1450.3 | 1643.8 | 1618.8 | 1665 | |

Max.output(KW) | Rated | 18.7 | 23.4 | 23.2 | 23.2 | 23.2 | 21.4 | 20.4 | 18.2 | 15.3 |

| Continuous | 27.7 | 34.9 | 34.7 | 34.5 | 34.9 | 31.2 | 28.8 | 25.3 | 22.2 | |

| Intermittent | 32 | 40 | 40 | 40 | 40 | 35 | 35 | 27.5 | 26.8 | |

Max.pressure difference(Mpa) | Rated | 16 | 16 | 16 | 16 | 16 | 15 | 14 | 12 | 10.5 |

| Continuous | 20 | 20 | 20 | 20 | 20 | 18 | 16 | 14 | 12.5 | |

| Intermittent | 24 | 24 | 24 | 24 | 24 | 21 | 18 | 16 | 13 | |

| Peak value | 28 | 28 | 28 | 28 | 28 | 24 | 21 | 19 | 16 | |

Max.inlet(L/min) | Rated | 80 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Continuous | 100 | 125 | 125 | 125 | 125 | 125 | 125 | 125 | 125 | |

| Intermittent | 125 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | |

Max.inlet pressure(MPa) | Rated | 21 | 21 | 21 | 21 | 21 | 21 | 21 | 21 | 21 |

| Continuous | 21 | 21 | 21 | 21 | 21 | 21 | 21 | 21 | 21 | |

| Intermittent | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | |

| Peak value | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | |

| Weight(Kg) | 19.5 | 20 | 20.4 | 20.5 | 21 | 22 | 23 | 24 | 25 | |

Hydraulic motor spare part and production line:

1.Hydraulic motor body BEFORE processing.

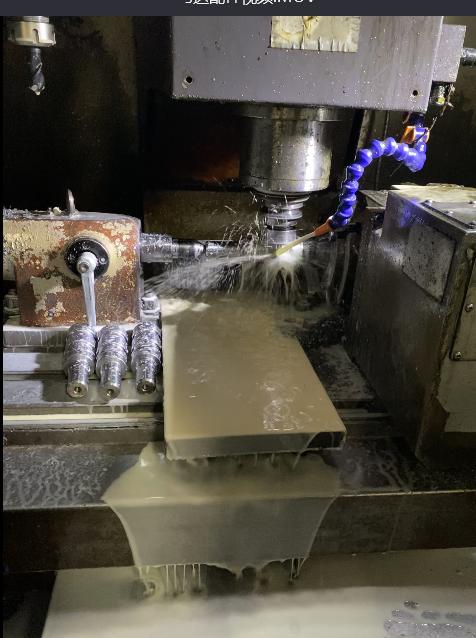

2.Picture of shell processing equipment.

3.Hydraulic motor body AFTER processing.

1. Hydraulic motor inside contact Shaft BEFORE Processing

2. Equipment for processing internal contact shafts

3.Hydraulic motor inside contact shaft AFTER processing.

1.Hydraulic motor drlve shaft BEFORE processing.

2.Hydraulic motor drlve shaft processing machine

3. Hydraulic motor drlve shaft AFTER processing.

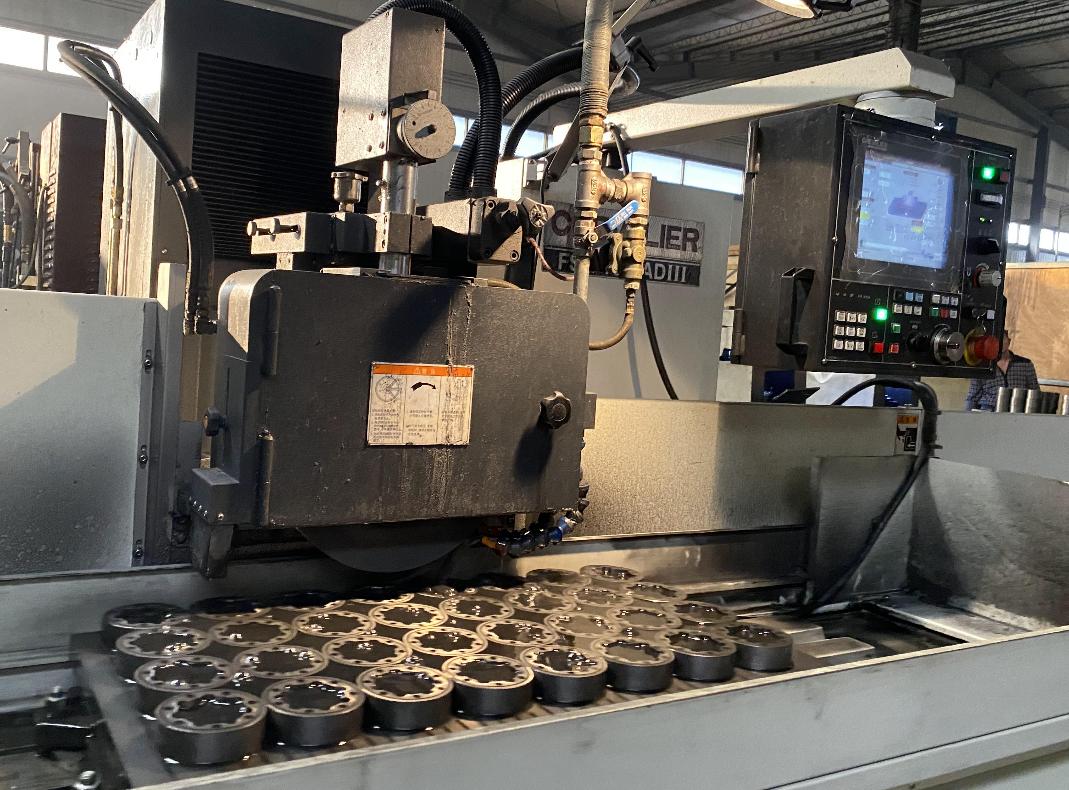

1.Hydraulic motor stator BEFORE processing

2.Hydraulic motor stator processing machine

3.Hydraulic motor stator AFTER processing

Outgoing pictures and product certification

中文

中文 English

English Español

Español Français

Français