{{i.title_en}}

Oxidized Contact Used In Low-voltage Electrical Appliances

MOQ: 500 PCS

Note: If you have any questions,please contact us

- The electrical contact products prepared by the alloy internal oxidation method have good compactness, small oxidized substances, resistance to arc corrosion, and long electrical life.

- Silver tin oxide, silver tin oxide indium oxide, silver zinc oxide, silver copper oxide, silver cadmium oxide and other contact products are added with trace elements such as nickel and rare earth. The low temperature and high pressure oxidation technolog

- Using smelting and atomization, combined with the pre-oxidation process, the grains of the material are refined, the structure is uniform, the microstructure is not segregated, the oxide-poor ridge area is eliminated, and the contact material with excelle

- Alloy oxidation contact products are widely used in low-voltage electrical appliances

- Can be developed and produced according to the specific requirements of users, with an annual production capacity of 120 tons

Longsun Group Co., Ltd

Since:

1986

Product Description

Features:

1.The electrical contact products prepared by the alloy internal oxidation method have good compactness, small oxidized substances, resistance to arc corrosion, and long electrical life.

2.Silver tin oxide, silver tin oxide indium oxide, silver zinc oxide, silver copper oxide, silver cadmium oxide and other contact products are added with trace elements such as nickel and rare earth. The low temperature and high pressure oxidation technology is used to achieve the effect of fine particle size and dispersion strengthening. Improve the mechanical strength of the product, improve the welding resistance, arc burning resistance and electrical wear resistance of the contact material.

3.Using smelting and atomization, combined with the pre-oxidation process, the grains of the material are refined, the structure is uniform, the microstructure is not segregated, the oxide-poor ridge area is eliminated, and the contact material with excellent performance is manufactured.

4.Alloy oxidation contact products are widely used in low-voltage electrical appliances

5.Can be developed and produced according to the specific requirements of users, with an annual production capacity of 120 tons

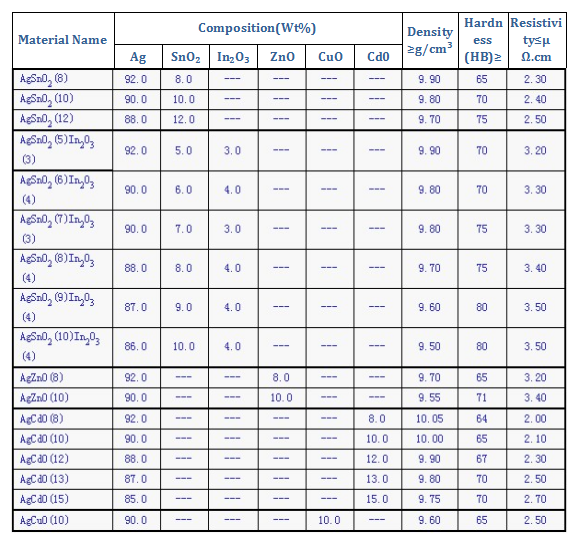

Material composition and physical mechanical properties of alloy oxidation contact products

中文

中文 English

English Español

Español Français

Français