- Development of rice huller

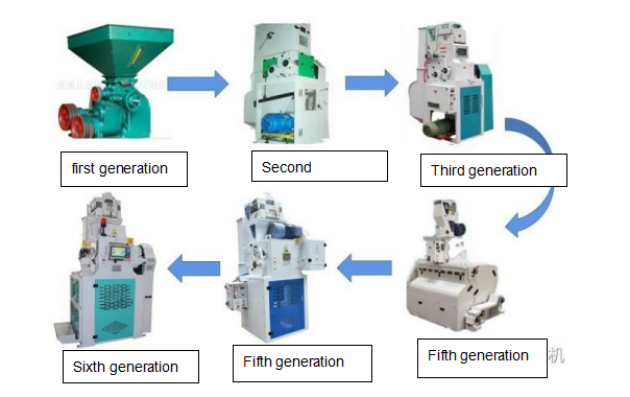

Rice huller has been one of the main products of CLJ's company for a long time.After decades of painstaking research and development, from the first generation of manual close-roll rice huller in the 1960s and 1970s to the fifth generation of intelligent pneumatic rice huller and the sixth generation of intelligent variable frequency rice huller, each generation of products embodies the wisdom and sweat of rice hullers.

- Working principle and function of rice huller

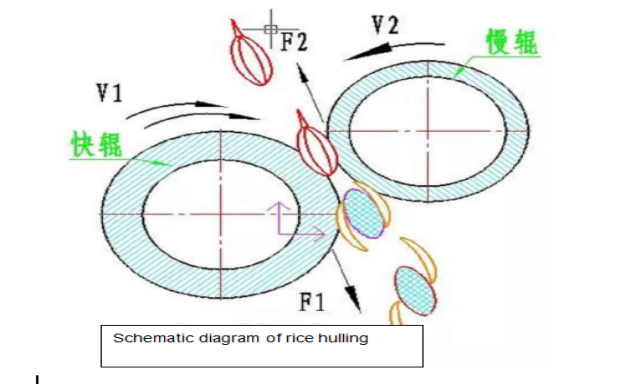

A pair of uneven rotation, in a certain working pressure of the rubber roller through the rice produced by rubbing tear husk.Rice hulling machine is mainly used for hulling rice and separating husk from rough rice, but it has been expanded to hulling rhubarb rice, small yellow rice, Tartary buckwheat, sorghum and other small cereals at present.Material go through drip plate institutions into the roller under certain pressure of rubber roller with elastic clamping or seize, rubber roller working surface compressive deformation, grain itself also compressive deformation, because of the fast roller and slow roller speed, rice grain produce some friction, the shell and the rubber roller surface to rub to tear and grinding effect on rice husk to achieve the purpose of hulling .

- Rubbing and tearing length, difference of thread speed and the relationship between thread speed and yield and rough crushing

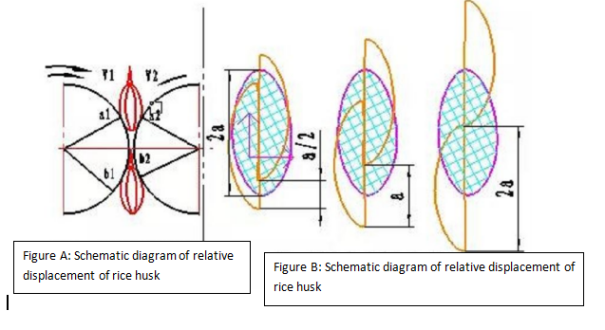

Rubbing and tearing length: as shown in Figure A, when rice enters and disconnects from the second rubber roller, the length of the contact arc between the fast roller and the slow roller is A1B1, and the length of the contact arc between the fast roller and the slow roller is A2B2, and the rubbing and tearing length is a1B1-A2B2. The rubbing and tearing length is one of the key factors affecting the hulling rate of rice.FIG. B;Assume that the length of the rice is 2 a, the left view of rub to tear length is only a / 2, Chinese only a (half the length of the rice, the rice did not fully release or hulling rate is very low, right yes rub to tear length is equal to or slightly greater than 2 a, has reached the limit of the shell completely, 8/5 are a can, can actually rice isn't rice varieties according to the optimization line speed difference;There is a positive correlation between the tearing length and the line speed difference V fast -V slow and the peeling rate. If the line speed difference is too large, it will increase the waist explosion, rough crushing rate and glue consumption, and even cause the side effects of rubber roller grooving.The sum of line speed is proportional to the output, and the sum of line speed is large, and the output is large. Generally, the ratio of line speed difference and line speed sum K=1.2 is the best (line speed difference 3m/s, line speed and 30m/s are more appropriate).

- Working mode and function of each part

Pneumatic rice huller consists of five main components: feeding mechanism, hulling device, driving and tensioning mechanism, intelligent control system and air separating device.

1)Intelligent digital vibration feeding mechanism:

The first is the vibration feeding part, which uses high frequency (50 times/second) and low amplitude (1.5 ~ 2.5mm) vibration to make the thickness of rice flow into the long drip plate uniformly, so as to ensure that the thickness of the material layer is consistent throughout the whole range of cots.

The second is the long drip plate part, its role has two;One is to accelerate the material to reach the best speed into the rubber roller, and make the material after accelerated thinning, basically keep a layer of material into the roller.The second is to play a rectification role, so that rice along the length direction of the big head down orderly arrangement into the cots, which either improves the rate of shucking and reduces the rate of broken rice.

2) Advanced and reliable hulling apparatus for hulling room .

Rubber roller for consumables, because in the process of use, speed of roller wear speed is not the same, in the process of work need to rubber roller for speed or fast speed switching, rubber roller supporting rigid structure are the key factors influencing the mechanical properties and process performance, series pneumatic adopted by the rice huller rubber roller patent auxiliary supporting structure, improving the working reliability of two rubber roller.

3)Innovative drive and tensioning mechanism

Pneumatic rice huller adopts synchronous belt drive structure, the synchronous belt is tensioned by tensioning pulley spring, which has low noise, stable transmission ratio and no slip of belt. Multi wedge belt drive, high transmission efficiency, low noise (less than 80dB).

As a one-stop solution provider of post-harvest processing of grain ,CLJ would like to provide high quality products and professional service to customers all over the world .

中文

中文 English

English Español

Español Français

Français